Explain Different Types of Metal Cutting Processes

Cold metal cutting is conducted with tools eg hacksaws files snips and cold chisels. Neutral flame carburizing flame and oxidizing flame.

Introduction To Metal Cutting Engineering Tutorials

The three common types of chips from a single point tool are.

. It is a finishing or semi finishing process by removal of excess material from work piece. The advantages of the welding process are many. It is portable because of pressurized gas filled in a handy steel cylinder.

Sheet Metal Operations. Low depth of cutting. Types of Tool Wear 3.

Factors Favorable to its formation. Milling is an important process of manufacturing technology and basically it refers to the removal of metal from the work piece using a tool which has several cutting points and is rotating about its axis. What are the four types of chips produced in metal cutting Continuous chips.

The excess material removes from work piece in form of chips. Slotting is the process of cutting rectangular holes onto sheet metal sometimes unfinished. Electron Beam Welding 8.

Metal fabrication is a somewhat broad term for several types of fabrication processes. Types and Classification of Metal Joining Processes 1. This material loses their hardness.

Introduction to Milling. Types of chips in Metal Cutting. Cutting punching forming shearing stamping welding are common fabrication techniques used to shape cut or mold raw metal material into a final product.

Thus each cutting point removes a little bit of the metal but since there are multiple such points and the tool is rotating at a fast speed. Removing and trimming and creating notches at. The operation is done when the metal is in red hot condition using a chisel and hammer.

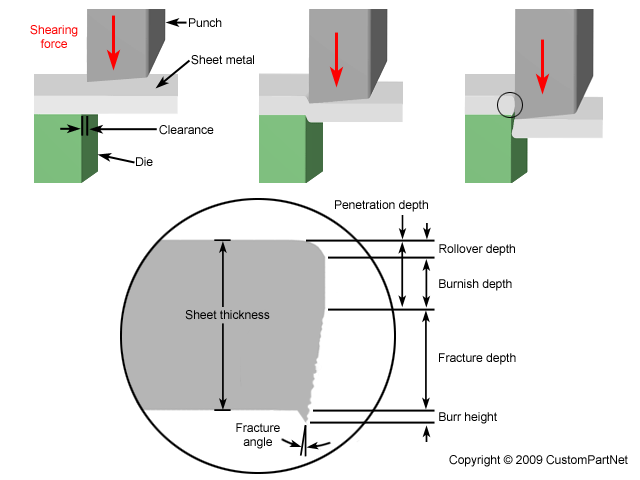

Metal Cutting Cutting processes work by causing fracture of the material that is processed. Meaning of Tool Wear 2. There are three types of chips produced during machining process.

The process involves three types of flames. Although the actual machines tools and. C large rake angle.

B high cutting speed. They are in metal-to-metal contact between the chip and work piece under high stress and temperature. Machining is a process of cutting metal work piece by means of a tool to convert it into desire shape.

To make proper cutting. Continuous chips with build-up edge BUE. It is a cut in a straight line across a strip sheet or bar.

The chips come out without fracture in the form of either long string or bend into a tight roll. The cutting tools work along two axes of motion to create cuts with precise depth and width. Less friction between tool face and chip.

That means the body of the cutting tool is made by other material and the cutting portion of the tool is made by some other material to join two different materials we use different types. Lathes are available in two different types the traditional manual type and the automated computer numerical controlled CNC type. Produced by brittle materials and consist of segments attached firmly or loosely to each other.

Notching is the process where shapes are cut from the edges of the sheet metal. High back rake angle. Solid Phase Welding at Elevated Temperature 2.

Flatbed die cutting is used on thicker metal materials and uses a dies on a press to cut out shapes when the die stamps down on the metal. Different types of forging defects Causes and their remedies Cutting. Water alone is a good heat conductor but we cannot use it as a cutting fluid because of its corrosive and non-lubricating action.

Relative Motion between workpiece cutting edge of tool. D sharp cutting edge. Cutting is a forging operation is carried out when metal is needed to be cut apart.

It consist of elements bonded firmly together without being fractured. This cutting tool is made of different types of materials. Without breakage then it is called as continuous types of chips.

Liquid coolant means an emulsion of oils in the water base. Liquid type cutting fluids. Cutting tools are subjected to an extremely severe rubbing process.

The different types of cutting fluid are used during the metal cutting processes. It leaves a lean edge on the piece of metal is sheared or cut. The turning process can be performed on either the exterior or interior of a material.

If this chip hit finished parts of the work it spoils the finished surface. Carbon tool steels possess good machinability. Die cutting is another cutting process that uses a die to slice metal.

Discontinuous or segmental chip. Meaning of Tool Wear. Usually the portion that is fractured away is in small sized pieces called chips.

Laser Beam Welding 9. The types are- 1. Other metal like Cr V are added to change the hardness and grain size.

These plain carbon steel cutting tool have the composition of 06-15 carbon and very small amount of less than 05 Mn Si. The upper side has small notches while the lower side is smooth and shiny. Common cutting processes include sawing shaping or planing broaching drilling grinding turning and milling.

Single Point tool. Continuous chips are formed when the ductile material is machined with high cutting speed. This article throws light upon the nine types of metal joining processes.

The main types of cutting fluid are as follow. If the tool is continued to move relative to workpiece there is continuous shearing of the metal ahead of the tool. Up to 24 cash back Metal may be cut by the means of hot or cold cutting processes and techniques.

After reading this article you will learn about- 1. Rotary die cutting uses a spinning cylindrical die to cut the material that is fed through a press. The metal undergoes shear type deformation and a piece or layer of metal gets repeated in the form of a chip.

Hot metal cutting is performed with oxyfuels which are a combination of pure oxygen and a combustible fuel gas eg acetylene MAPP gas propane and natural gas. Formed with ductile materials machined at high cutting speeds andor high rake angles. High carbon steels are abrasion resistant and have the ability to maintain sharp cutting edge.

Whatever the cutting conditions can be the chips produced may belong to one of the following three types. If the metal chips formed during machining is without segments ie. Fabrication is distinct from other manufacturing processes.

Continuous chip obtained when cutting of ductile material like aluminium and low carbon steel.

Various Operations On Lathe Mechanics Educational Materials Lathe Machine Lathe Machine Parts Metal Lathe Projects

Comments

Post a Comment